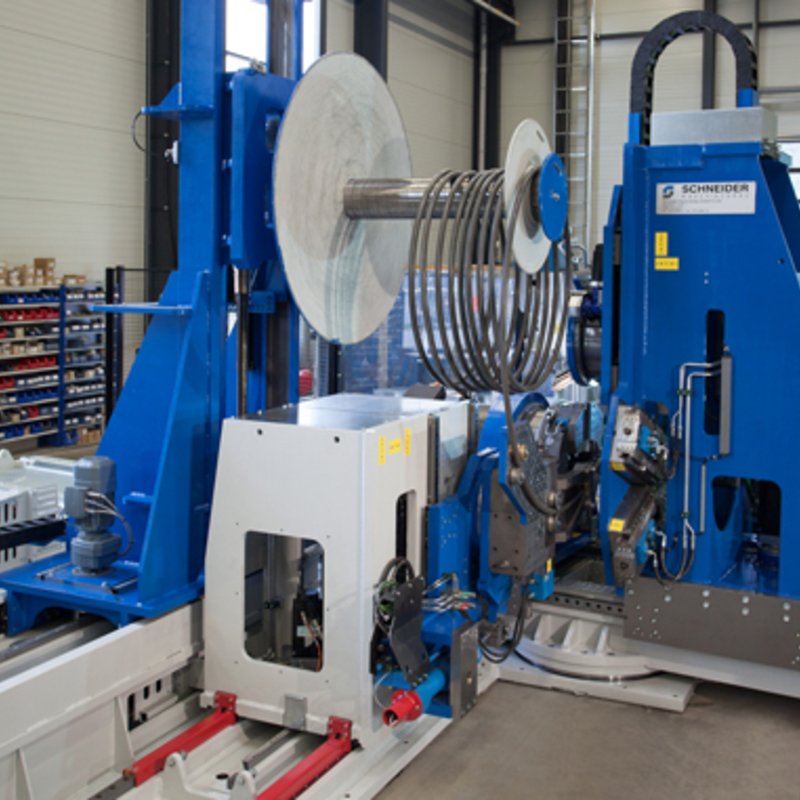

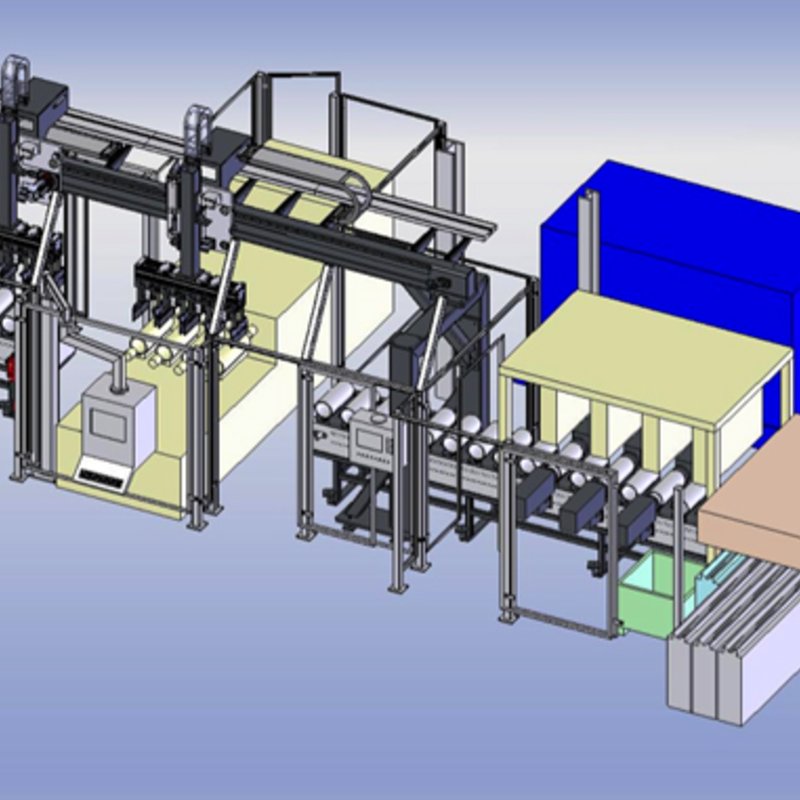

Setting and testing systems for suspension springs

Quality in vehicle construction

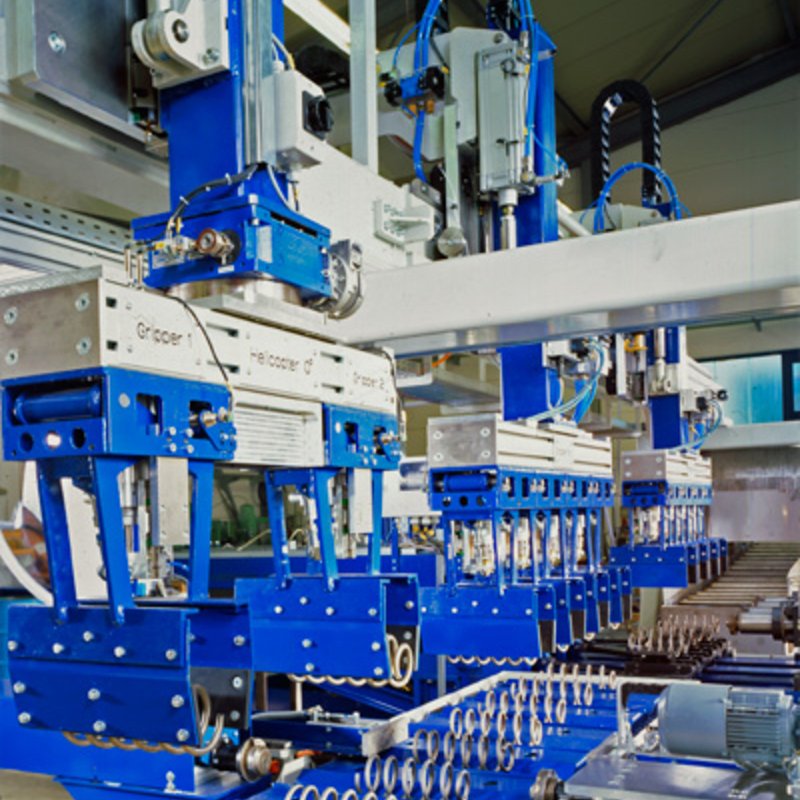

Torsion springs used as stabilizers and suspension springs are among the most safety-critical components used in state-of-the-art chassis technology. By compensating for irregularities in the road, they ensure that the wheels always remain in firm contact with the ground and that the vehicle can be steered safely. At the same time, they ensure a high level of ride comfort, as they protect the occupants from up-and-down, pitch and roll movements, as well as impacts.