FFP2 masks Made in Germany

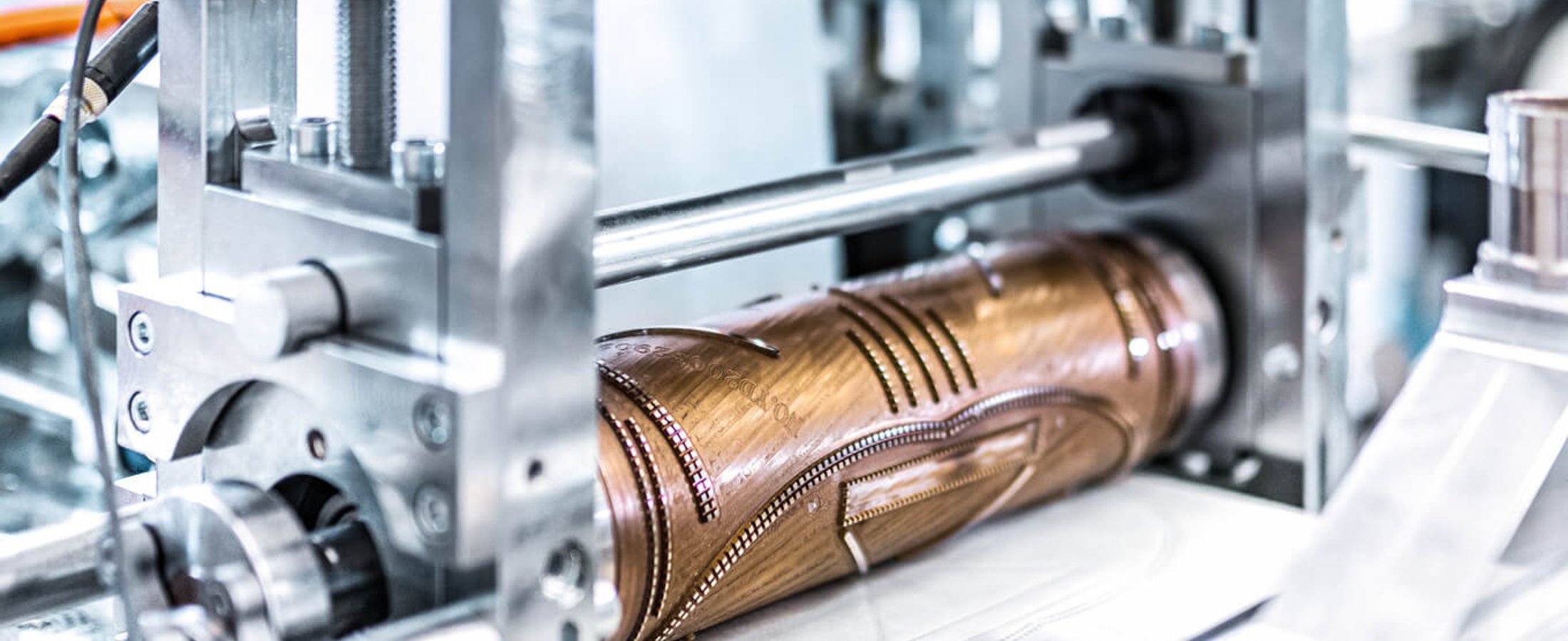

Since the beginning of the pandemic, Schneider Technologies has been working very detailed and conscientiously on the development of its own FFP2 protective mask and on the production technology required for it. Increase your efficiency with a mask machine classified as highly innovative by the German Federal Ministry for Economic Affairs and Energy..