Chemical-free paint stripping

Inductive paint stripping – fast and environmentally friendly

If the paint of a vehicle or machine is damaged and there is a risk of rust, paint stripping must be carried out. In many cases, chemicals are used for this purpose, which entail health risks and endanger the environment.

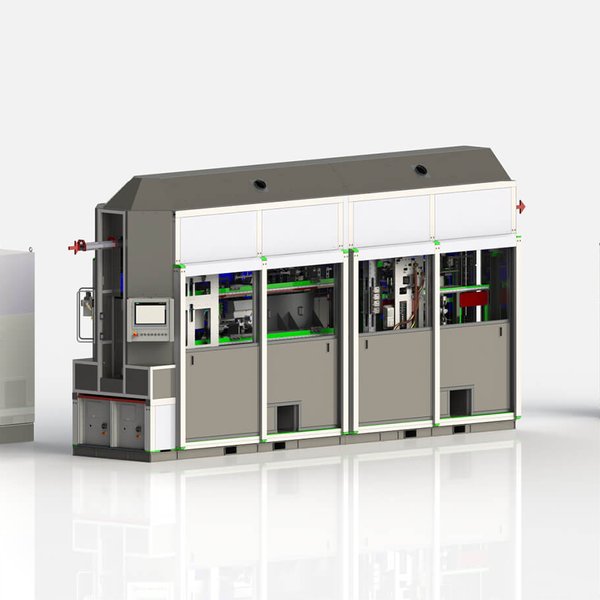

We use no chemicals in our paint stripping systems and instead rely on conductive and inductive heating.

Chemical-free paint stripping suitable for a broad range of industries

Paint stripping and decoating through conductive and inductive heating are suitable for all companies looking for an efficient solution for removing paint coats from components without polluting the environment or putting the health of their employees at risk.

The main fields of application of our machines include:

- Metal construction

- Industrial sheet-metal working

- Automotive industry

- Mechanical engineering

- Pipeline construction