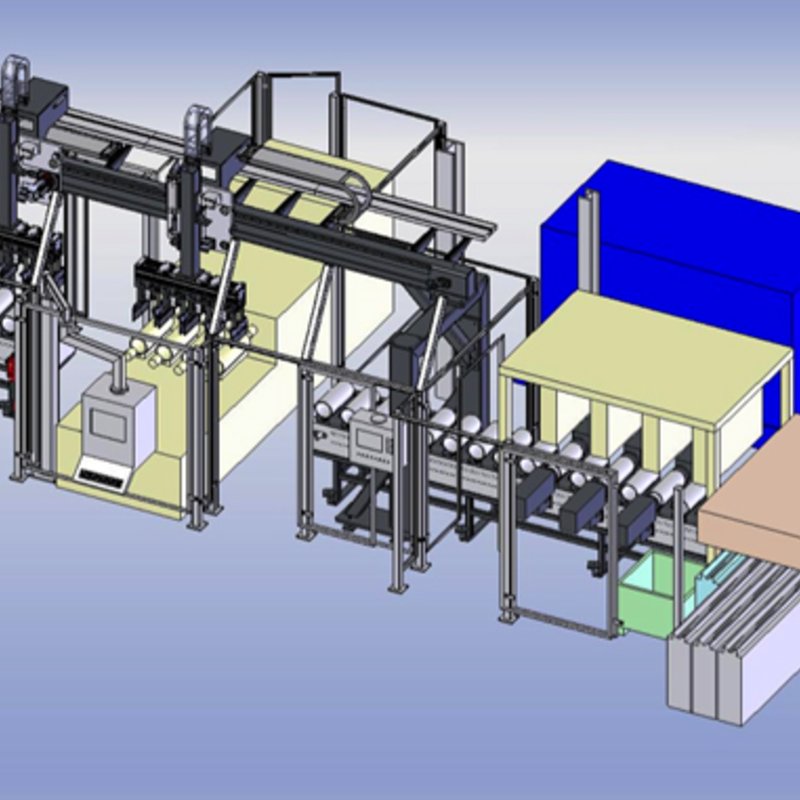

Testing and marking systems

Ensure high security

Suspension springs are the link between the wheels and the chassis. They are among the most safety-critical components of a modern vehicle and influence handling, roadholding and braking behavior. Accurate testing and labeling are therefore essential to ensure the safety of the parts.

Fully automatic and semi-automatic systems are also available for the assembly of rubber bearings and clamps, in which defined test characteristics are monitored.

Translated with www.DeepL.com/Translator (free version)