1. Planning

During project planning, we clarify technical details, draw up a concept of the technical process of the machine, and consider how the system will be integrated on site. On this basis, we provide you with a binding offer.

2. Engineering

We design your system on a digital basis. Complex calculations and simulations ensure the stability of the plant and serve as a basis for robot programming. Electrical planning and technical documentation round off our engineering.

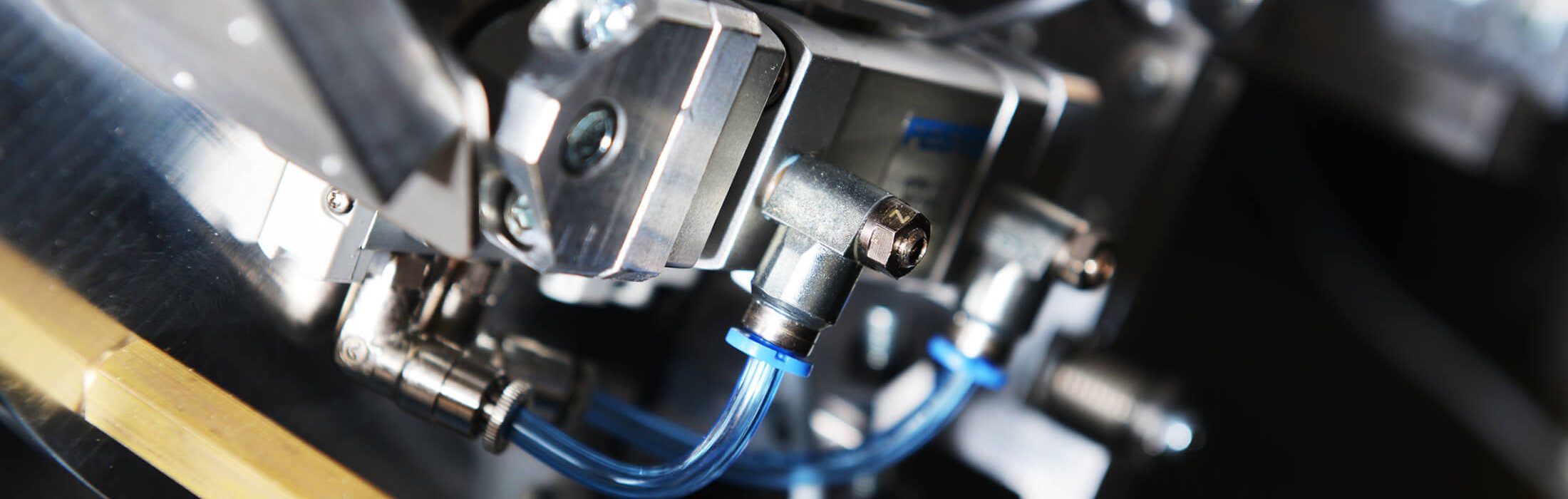

3. Manufacturing

On the basis of the digital data, we manufacture the components of your machine. We rely on the use of our CNC-controlled 5-axis milling machines and the possibilities for eroding, edge forming, turning, drilling, and surface grinding. Individual welded constructions form the basis of your system. Coatings aid in maintaining the value of the construction.

4. Assembly

We assemble your machine from individual assemblies and parts and install electronic components, including programming. We carry out trial production on our premises to ensure that all performance criteria are met. If it runs to our full satisfaction, we deliver your machine. Anywhere in the world – including customs clearance.

5. Commissioning

On your premises, our experts carry out the setup. After the final test run and final acceptance, we hand over the production-ready special machine to you.

6. After Sales/Service

Maintenance contracts and deliveries of spare and wear parts ensure the availability of your machine. Remote maintenance modules enable us to support you from afar.